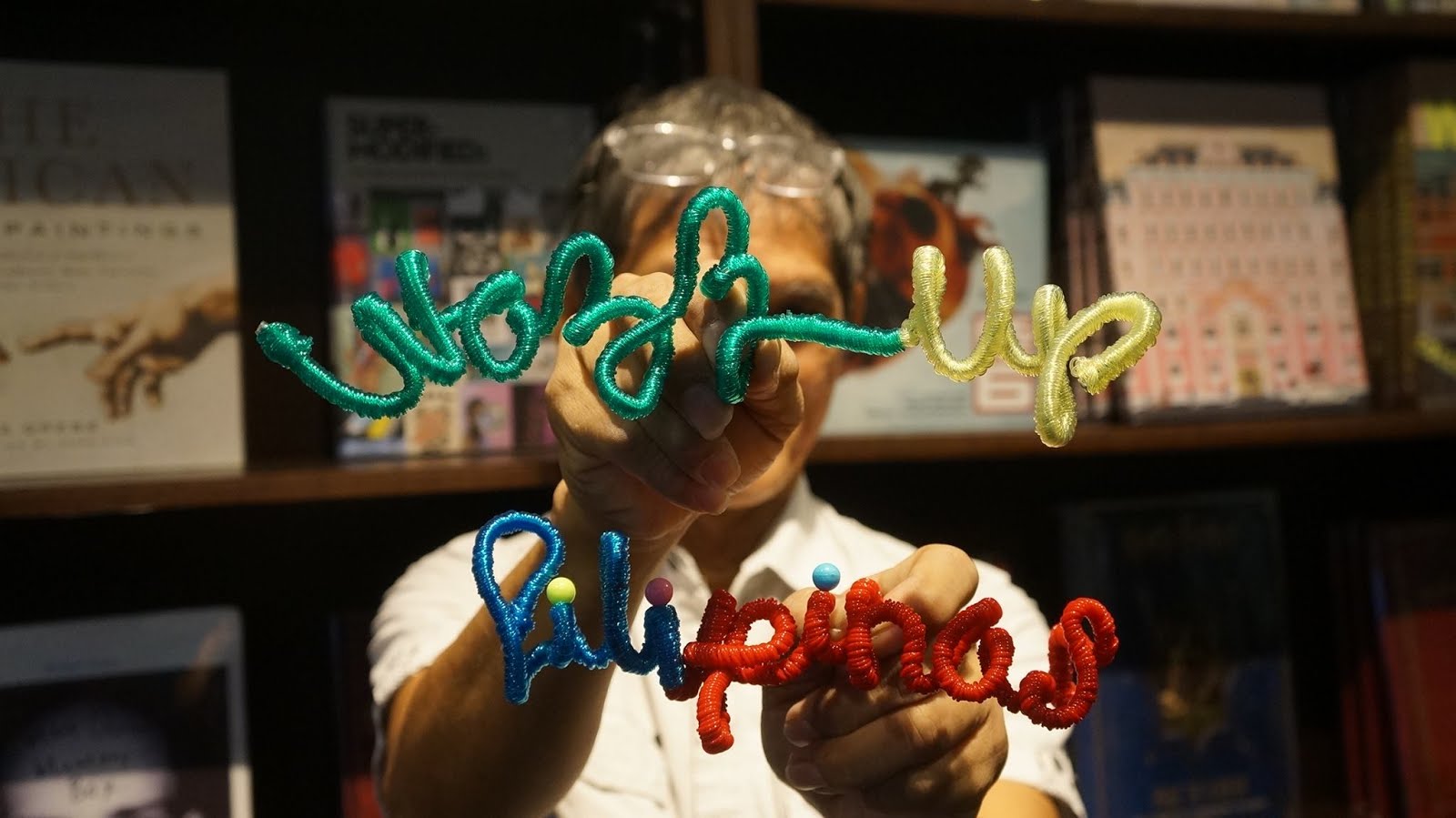

Wazzup Pilipinas!?

In a world increasingly being aware of the environmental footprint of industrial processes and products, the quest for sustainable solutions has become paramount. Fortunately, we have come to see a groundbreaking invention – the Carboxymethyl Hyaluronic Acid (CMHA) Hydrogels, a true game-changer in diverse sectors ranging from healthcare to textiles. This invention was created in the busy laboratories of the Philippine Nuclear Research Institute of the Department of Science and Technology (DOST-PNRI).

The Invention

CMHA Hydrogels are derived from hyaluronic acid, a compound renowned for its multifaceted biological functions, including promoting cell migration and proliferation. In general, hydrogels are materials that can hold large amounts of water in their 3-dimensional structure. This ability to retain water makes hydrogels unique and useful for various applications. What sets CMHA apart is its production process, which eschews toxic agents in favor of a green approach utilizing only water and radiation. This not only ensures a high-purity product but also underscores its eco-friendly credentials. For instance, it can provide a moist environment around the wound and support the healing process.

CMHA hydrogels were created using green technology which means that they are prepared without chemical additives and at ambient temperature. They are derived from hyaluronic acid which has diverse biological functions and the addition of the carboxymethyl group imparts additional functionalities. Without toxic crosslinking agents, our hydrogels exhibit exceptional biocompatibility. “Before we can prepare the hydrogel, we have to synthesize CMHA since it is not commercially available. Scaling up the synthesis of CMHA is not easy – the purification and drying steps are tedious and long because we do not have the needed equipment. We were able to do it with tenacity and patience”, said Ms. Relleve when once asked about the struggles and challenges they faced during the development of their invention.

Versatility and Advantages

One of the most remarkable aspects of CMHA Hydrogels is its versatility. With properties adjustable via irradiation dose, these hydrogels exhibit a wide range of swelling capabilities,making them ideal for various biomedical applications. From wound dressings to ocular treatments and drug delivery systems, CMHA Hydrogels offer a safe, biocompatible alternative to conventional products, free from toxic residues.

The competitive advantage of CMHA Hydrogels lies in its carboxymethyl group, which enhances hydrophilicity and water-absorbing capacity. This, coupled with its biodegradability and stimuli-responsive swelling properties, positions CMHA Hydrogels as a frontrunner in sustainable material innovation. Moreover, its exceptional safety profile makes it a preferred choice across industries, from pharmaceuticals to cosmetics and beyond.

The Creators

The journey from concept to reality has been fueled by the relentless dedication of the PNRI team, led by inventors Lorna S. Relleve, Alvin Kier R. Gallardo, Mariel G. Tecson, Lucille V. Abad, and John Andrew A. Luna. Their vision, coupled with PNRI's commitment to advancing nuclear science for peaceful applications, has culminated in a groundbreaking invention poised to leave an indelible mark on the global stage.

“We want to develop hydrogels by radiation technology that has superior quality and can be used safely in various applications that can enhance the quality of life,” said Ms. Relleve when asked what inspired them to develop this invention.

“We are motivated by the opportunity to bring our vision to life and make meaningful contributions in the field of radiation processing and to make a difference in the world,” she added.

Ms. Relleve, who has been with the DOST-PNRI for three decades, spearheaded the research and development of the CMHA Hydrogels. She has always been fond of polymer modification through radiation, especially for various hydrogel applications. She, together with her team believes that success is when they can publish their work to have it patented, and eventually commercialize.

Commercial Vision

As the global Hydrogel Market continues to expand, with projections reaching USD 32.62 billion by 2029, the potential for CMHA Hydrogels is immense. From apparel and home textiles to industrial applications, the demand for sustainable materials is on the rise, presenting a lucrative opportunity for innovators and investors alike.

The CMHA Hydrogels epitomize the marriage of innovation and sustainability, paving the way for a greener, healthier future. With its myriad applications and untapped potential, this invention stands as a testament to the power of scientific ingenuity in addressing pressing global challenges. As of now, the CMHA Hydrogels have not been deployed yet, but prototypes are available. However, further research and development works are needed to use them in various medical applications.

As we embark on a journey towards a more sustainable world, CMHA Hydrogels serve as a beacon of hope, inspiring us to push the boundaries of what is possible and usher in a new era of responsible innovation.

** This feature is a part of the "Shape the Future" campaign, highlighting nine Philippine inventions featured in the 49th International Exhibition of Inventions Geneva (IEIG) on April 17-21, 2023. Competing for gold awards, these innovations also aim to promote local technologies for potential international technology transfer and commercialization.

By Matt Jerome Casequin

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.