Wazzup Pilipinas!?

In the buzzing laboratories of the Department of Science and Technology - Philippine Textile Research Institute (DOST-PTRI), a group of visionary minds led by Mr. Ronald Pechera, Mr. Karl Marx Lennin Florante, Mr. Emmanuel Victor Buniao, Mr. Noriel Sorsone, Mr. Jenneli Caya, and Dr. Julius Leaño, Jr. has embarked on a journey to reshape the textile industry. Their Invention? The Lyocell or Natural Fiber-Blended Yarns, a sustainable substitute aims to transform the way we think about textiles.

The European Parliament has published an article on the environmental impact of textile production and waste. According to the article, it takes a significant amount of water and land to grow cotton and other fibers used in textile production. An estimated 2,700 liters of fresh water are required to produce a single cotton t-shirt, which is equivalent to the amount of drinking water one person would need for 2.5 years.

Identified as the third biggest contributor to water pollution and land use in the year 2020, the textile industry, it consumed an average of nine cubic meters of water, 400 square meters of land, and 391 kilograms of raw materials to produce clothes and shoes for every citizen in the European Union.

When we wash synthetic clothing and fabrics, it can lead to the release of over half a million tonnes of microplastics into the ocean every year. This is a significant global issue. Furthermore, the production of garments can generate pollution that causes harm to the health of local people, animals, and ecosystems where the factories operate. It's a devastating problem that requires immediate attention.

As per the European Environment Agency, the textile purchases made in the European Union in the year 2020 produced around 270 kg of CO2 emissions per individual. This means that the greenhouse gas emissions generated by textile products consumed in the EU amounted to 121 million tonnes.

Lastly, the fashion industry is responsible for approximately 10% of the global carbon emissions, which is more than the combined emissions of international flights and maritime shipping.

Quality and Sustainability

At the core of this innovative approach lies a meticulously refined process designed to transform pineapple leaf fiber, banana fiber, and abaca fiber into a spinnable form. This process constitutes a pivotal step in the production of yarn. Different from conventional methods, this technology overstates a closed-loop system, lessening water utilization by 20 percent and reducing environmental effects by reusing non-toxic solvents.

Lyocell isn't just environmentally friendly, it's also renowned for its superior quality and durability. As compared to synthetic fibers like polyester and rayon, Lyocell offers a decreased carbon footprint and enhanced durability, surpassing even natural fibers like cotton and viscose.

Lyocell fabric is incredibly strong, whether it is wet or dry, and it is more resistant to pilling than cotton. Textile manufacturers appreciate that it is easy to combine this fabric with other types of textiles. For example, it pairs well with cotton, silk, rayon, polyester, nylon, and wool.

Utilization and Impact

The Department of Science and Technology - Philippine Textile Research Institute (DOST-PTRI) has been actively collaborating and forging partnerships with textile manufacturers and handloom weaving communities all across the Philippines in order to bring their vision of sustainable textile production to fruition. Through their tireless efforts, they have succeeded in creating a range of high-quality fabrics that have been transformed into stunning garments and home textiles by talented local and native fashion designers. As a result of their dedication to sustainability and innovation, these textiles have gained widespread recognition both locally and globally, serving as a shining example of the immense potential that sustainable textiles hold in today's fashion industry.

Market Potential and Future Vision

With the European textile garment market projected to reach USD 256,144.90 million by 2030, there's a growing demand for eco-conscious alternatives among consumers. Lyocell's superior quality and sustainability position it as a frontrunner in the international textile market, especially as European shoppers increasingly favor sustainable and economical fashion.

For the PTRI alliance, putting forward their innovation to market is about more than commercial success. It's about revolutionizing the textile industry and reshaping the whole landscape surrounding production and consumption. Focusing on the perspective of sustainability, innovation, and inclusivity, they aim to create a future where textiles play a central role in framing a more equitable and regenerative world.

Lyocell and Natural Fiber-Blended Yarns are not just a technological breakthrough but a ray of hope for a more sustainable future. These yarns have superior quality, reduced environmental impact, and promising market potential, making them poised to revolutionize the textile industry. They are paving the way for a greener, more sustainable tomorrow, and it's exciting to see the positive impact they'll have on our planet.

** This feature is a part of the "Shape the Future" campaign, highlighting nine Philippine inventions featured in the 49th International Exhibition of Inventions Geneva (IEIG) on April 17-21, 2023. Competing for gold awards, these innovations also aim to promote local technologies for potential international technology transfer and commercialization.

By Matt Jerome Casequin

Photos Courtesy: DOST-Philippine Textile Research Institute

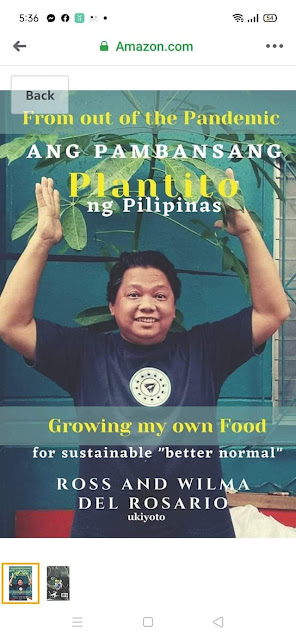

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.