Wazzup Pilipinas!

Historical Relevance

The journey of cardboard boxes starts in Germany in the year 1817. It was the first time that it was used as a commercial product in England. Later in 1840, the French were the first people to use this type of packaging for shipment. The first product to be shipped was silk producing moth and its eggs by fabric manufacturers of Valreas. About a century later, with the increase in the consumption of boxed breakfast cereals, cardboard boxes became an essential item for the marketing and retailing process.

Pre-cut cardboard boxes were made without intention by a Scottish painter in America around the year 1870. The following four years saw the construction of the biggest production house of corrugated board boxes in New York which produced the type of cardboard which is used in making boxes in today’s time. The year 1900 saw the replacement of wooden boxes with cardboard boxes for shipment purpose.

Processing material

Usually, these boxes are made out of a pine tree. To ensure that the natural resources remain intact, companies are using the vast areas of lands to grow these trees. Using this technique, new plants are quickly planted when the old ones are harvested. Cardboards are usually made from softwood plants, and therefore they result in soft and bendable material for packaging. The term cardboard is replaceable as it is not vast enough to depict all types of box materials that fall under this category. Some common material names used for the manufacturing process are:

1- Paperboard - 0.25mm thick cardboard

2- Fibreboard - a corrugated box made out of paper

3- Paper – sleek material for packaging and designing

4- Hardwood – to make heavy cartons for shipment

Environmental factors

Cardboards are a good alternative for the regular material that is plastic. The time it takes for the plastic to go near decomposition is more than 2000 years. This is an alarming situation, and therefore, many companies prefer using recycled material to make cardboard boxes. The main element used in the manufacturing of a cardboard box is a flute which is placed in-between two liners. A flute is a recycled board while liners are sheets that encase it. Old cardboards or the used paper is generally used as a flute. This trick prevents the cutting down of more trees for creating something that is not even visible while also reducing the amount of smoke that will pollute the Earth during production.

Styling phase

Shaping the marketing industry with high-quality designs and patterns, cardboard boxes are making a breakthrough with each passing year. Since the year they were first produced to the latest date, new ways to beautify the packaging are being introduced in the production houses. To match the needs of the specific products, die cutting is regularly used. By shaping the box in a way that suits your demands makes

cardboard boxes a flexible choice in the marketing point of view. Styling the containers with vibrant colours and quality artworks makes them stand out in the market. Customization of these boxes is the main focus of almost every brand so that the box can be recognized as their own and let the customer understand which company is looking after their needs and is aiming for their satisfaction.

Latest problems call for the latest solutions, and that is why computers are being installed in the manufacturing process to print the boxes. Digital printing is coming up in the market as the customers are demanding for it more and more every day. State of the art software and image graphing tools are at the disposal of skilled technicians who waste no time in turning the paper-based design to pixels.

Manufacturing

1- Raw form

Trees from special lands are brought down to the production houses to be processed into becoming good cardboard. This cardboard is then turned into a box. Pine and fir trees are special selections of the harvesters because of their long fibers. These fibers are entangled with each other, and thus, they provide an element of strength and agility to the cardboard. The fewer breaks there are in the wood, the smoother will be the texture of the box in the end.

2- Pulping

The timber collected is then cut down into wood chips. A batch digest is used for cooking the stripped pieces of wood. While the digester is mixing the chips in a special solution, a hint of the selected amount of sodium hydroxide is added in the process. This is an important part of pulping as it helps to hold each string of the wood firmly. A certain amount of pressure is inserted in the cooker, and when the pressure reaches a limit, it’s only then that wood completely breaks down and becomes a mass of fibers. This pulp like substance is then passed on for further processing.

The next step is to push this material to a Fourdrinier machine which converts this mush into a decent looking paper. As soon as the paper is formed, it moves on to pressure rollers that process the raw form of paper into a well-textured paper. From there, the paper is selected to become a good choice for the kraft paper.

Kraft paper is used as a medium and a liner for the making of corrugated cardboard. The choice of the type of paper lies with the customer, and their requirements as the selection of this ingredient determine the strength of the box.

3- Corrugation

A corrugator is a machine that is used in this step. It takes a roll of corrugated cardboard at one roller and rolls it with the liners from another roller only to be glued together into a flat surface. This surface is known as a bridge. Automated machines are designed in such a way that process is continuous, thus confirming the quality of the final product and resulting in no loss of speed.

To integrate the cardboard, liners, and mediums altogether, a certain amount of set heat is applied in the final stage of corrugation. About 350 to 365 degrees Fahrenheit is applied to the cardboard mixture.

4- Sculpturing

Finally, the cardboard is ready to become a box. It is time to cut the card according to the requirements of the box that the client has asked for. Machines are set up in a particular order to cut the cardboard according to the demand. Once cut, a device called trimmer takes the pieces to it for stencilling the flaps, cuts, or designs that are required on the customized packaging.

Here the final product is also monitored in order to score it. Once the box passes the test, it is forwarded to an assembly line.

5- Integration

Here the final touches are made in the box. All the unnecessary pieces are cut off and sent to the recycling process to be used in the making of other corrugated cardboard packages.

Standardization

If not unique, the manufactured product should at least meet the industry standards that are being set by the companies already working in the market. For this, a number of tests are designed at almost every phase. The rules and benchmarks are set by market experts and capable design teams that have a detailed knowledge about the production of the boxes as well as what the customer is looking for in their packaging. All these rules make sure that when the cardboard passes through that particular field, it touches the set standardization bars.

Tests like The Cobb test are used to ensure the moisture intensity of the box whereas for steps of gluing, bursting, and compression, a separate test is designed and implemented. All the boxes are different in their size and nature. Therefore, all the containers take a customized dimensional test to prove their worth. After being through all these automated assessments, boxes move on to the possession of skilled workers at the near end of the production cycle. Before going to the final step, people check that no disrupted or damaged box is passed on.

What’s next?

New techniques are being pondered upon in order to make the manufacturing process even more advanced. Improvement in the material and steps can get the production to take a positive step ahead in the future.

With the Earth being on the verge of warming up a considerable number of degrees in the coming years, elimination of haphazard materials has become necessary. For this corrugated boxes are the preferred choice in the current market. Opposing the use of plastics and big wooden crates that serve the same purpose as these biodegradable boxes, the choice of opting for a reasonable material is very obvious. A significant drop in the consumption of plastics in leading countries has ultimately made the world turn towards this form of manufacturing.

It is a relatively smart solution, like the use of trees from specified areas is always encouraged. Those farms help to balance the equation and not let the cutting of trees make a lot of changes in the environment itself. It falls down on the shoulders of leading pioneers like yourself to take this initiative seriously and lead the world of marketing to a better place.

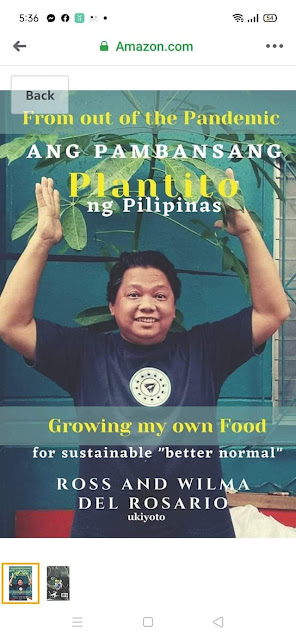

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.