Digitalization presentation on F&B industry by Roland

Heymann, Head of Global Food and Beverage, Technical Account Management,

Siemens Germany

At

the full-day seminar on “Digitalization of the Food and Beverage Industry in

the Philippines” held by Siemens last month, a team of global experts from the

company showcased their technological expertise to current and potential customers

in Philippines’ F&B industry.

Through interactive presentation sessions, Siemens presented

how

industry players can discover

the potential of digitalization in food and beverage industry. Topics covered include “Digitalization - The future of manufacturing in Food

and Beverage” and “Standardization –

Set the pace for digitalization in Food and Beverage”. There was also a live demonstration to

showcase how companies can “Reduce

downtimes and cost with transparent operation”, where Siemens used the example of

the dairy industry to demonstrate how both process and discrete workflows in

the food and beverage industry can benefit from digitalization. Factors

typically affecting the dairy industry are high cost sensitivity and mass

production on the one hand, coupled with the growing diversity of available

flavors and innovative packaging concepts on the other.

“We’ve

been working with a number of global food and beverage players and learned from

them about their demands and specific trends in the market. In order to respond

to these needs, we are adapting our digital enterprise software suite

accordingly and are implementing these functions into our applications, our

solutions, and our products. While doing so, we aim to bring those solutions to

anywhere in the world that has major expansions and investments ongoing for the

food and beverage industry, to give all regions and specifically the

Philippines an equal and fair chance to leverage our learnings,” shared Roland Heymann, Head of Global Food and Beverage,

Technical Account Management, Siemens Germany.

Digitalization the Food

and Beverage in Industry in the Philippines

The F&B industry in the

Philippines is a highly competitive one, and it is expected to amount to

approximately US$26 million in revenue this year. For manufacturers in the

industry, operating productive production facilities requires many factors for

consideration, including a consistently high level of product

quality, maximum plant availability, optimum resource efficiency – and,

increasingly, the greatest possible flexibility in order to meet more and more

individual customer requirements.

Additionally, about 1.3 billion tonnes of food – which is

about a third of all that is produced – around the world is wasted due to

factors such as poor equipment, transportation and infrastructure, rejection

due to aesthetics, and over purchase. The supply chain has to be more agile to

allow companies to produce the right amount of products to cater to consumer

demands, at the right time and at the right location.

Mastering all these challenges today and in the future is

possible only with digitalization. Digitalization

is the interaction of the virtual and real world. It is a major trend and

innovation driver, creating completely new business and growth opportunities

for companies. Digitalization of the entire value chain is crucial for catching

new trends and ensuring competitiveness.

This is particularly important

for the Philippines, as the country is growing rapidly in terms of population

and production capacities. Digitalization would lay the foundation of how the

local food and beverage industry will perform in the next few years and be able

to compete with other countries in the region.

The digitalization of the manufacturing industry, which

is also known as “Industrie 4.0”, is a topic of global interest.

Siemens

offers the products and solutions required fully or gradually integrate and

digitalize the entire value chain. The Digital

Enterprise Suite is Siemens’ answer to Industrie 4.0, and it enables

manufacturing companies to streamline and digitalize their entire business

process, seamlessly integrating suppliers into the mix. They can begin at any

point of their value chain, from product design to service, and can extend

digitalization gradually, depending on their current needs.

With the Digital Enterprise Suite,

Siemens offers a comprehensive portfolio of software-based systems specifically

for the discrete industries. It integrates and digitalizes the complete value chain

from Product Design, Production Planning, Production Engineering, Production

Execution to Services. The result of the integration and digitalization of the

complete value chain is a perfect digital copy of the value chain – the Digital

Twin. This enables companies to perform simulation, testing, and optimization

in a completely virtual world – before ever committing any resources in the

real world. The connection of the virtual and real worlds leads to shorter

time-to-market as well as greater flexibility, quality, and efficiency.

Enrico

Buergo, Vice President and Country Division Lead, Siemens Philippines, said, “Digitalization is an integral part of

the industrial revolution. You have this shift coming, it’s about the analysis,

integration and standardization. We’re bringing it here to kick-start a very

vibrant market which is food and beverage... and we really want to use it as a

way for each company to achieve whatever it is they are aspiring and not to be

left in the game.”

“The

future is always in motion,” explains Alexander Grimm, Head of Food and Beverage ASEAN,

Siemens Singapore, during the beginning of his presentation session. “Digitalization itself, it’s a thing which is in movement. It’s a continuous development.” He later explains in detail how

customers have become more discerning in terms of the wants, and how

digitalization in production can address these needs at the quicker and more

precise way.

Present in the seminar

were key officials of Siemens from both the regional and global headquarters

including Enrico Buergo, Vice President and Country Division Lead, Siemens

Philippines; Alexander Grimm, Head of

Food and Beverage ASEAN, Siemens Singapore; Roland Heymann, Head of Global Food

and Beverage, Technical Account Management, Siemens Germany; Christopher

Roppelt, Key Expert for Food and Beverage Automatic Concepts, Siemens Germany;

and Lito Torres, Head of Factory and Automation, Siemens Philippines.

As part of the

company’s commitment to the F&B industry in the Philippines, Siemens will

be offering a two-day workshop that would showcase in detail products and

technology that can be personalized and applied to their operating processes.

The workshop will be conducted by product specialists and will be at no cost to

participants of the seminar. Those who are interested can get in touch with

their Siemens representative.

For more information on

Siemens offerings in the F&B industry, please visit https://www.siemens.com/global/en/home/markets/food-beverage.html

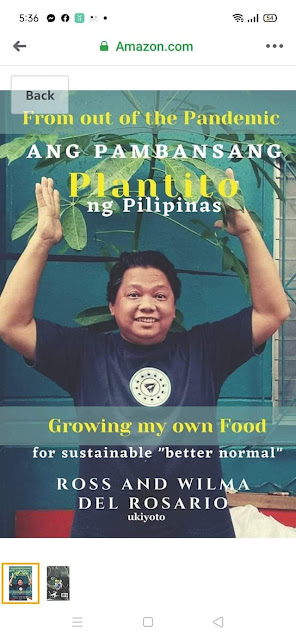

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.