Wazzup Pilipinas!?

Most blades are made from steel, copper, iron, and other metals; however, there are occasions when you need a unique blade that can withstand various conditions. On such occasions, your best option should be a titanium known for lightness, stiffness, durability, and amazing looks. Titanium is rare and hardly used for blades except when you need something versatile or for special purposes. It is rust-resistant, durable, and stiff, unlike other metals, making it perfect for blades used for different machines.

They look similar to other blades; however, you can only know their value when using them. As an alloy, it is harder and indestructible, making it ideal for special blades and not any other ordinary blades. For aesthetic appeal and heavy-duty uses, the titanium blades should be the best option for various cutting jobs and activities. If you want to try out some titanium blades, here are some potential uses and types of blades to try.

Common Uses of Titanium Blades

Titanium is an ideal choice for blades for different uses, ranging from knives and swords to large blades like those used on ship propellers, lawn moves, and farm tractors. Another common use is for jet engine propellers and other devices requiring lighter rotating blades.

It is perfect for bigger blades like propellers, lawnmowers, plows, and other uses. Unlike other blades, they are not common due to prices and mineral availability; hence, they are hardly used for smaller blades like kitchen knives.

It is not perfect for smaller kitchens, pens, and military knives. This is because when the surface is extremely thinner, it is less effective for cutting and can easily get damaged. It is perfect for blades of thicker densities, like those used in cutting machines or swords.

Another use for sawing blades that require harder metals to cut and clean others without getting damaged. For an ultimate and smoother cut, the titanium blade is the perfect saw blade to save you the cost of buying new blades all the time. Due to its heat resistance capabilities, you can use it longer without replacements or damage to the saw blades.

Why Use Titanium for Blades

Titanium blades are not very common; however, there are specific reasons why one would gain more interest in having them. Here are some reasons

Impact-Resistance Blades

Titanium is your best option if you need blades that can constantly interact with hard objects like rocks without damage. Despite the impact, it hardly dents, and neither will you feel the shock and vibrations. This is due to its density and stiffness, making it suitable for tools needed for farming and cutting. Due to the impact resistance, it is durable, and you will hardly notice any cracks even after using it for long.

Titanium has the best reputation as one of the strongest metals in the world. It can survive various conditions, including rust; hence, blades made from titanium will likely be durable and effective for various machines. This explains why they are used for sea and air vessels. The jet engine and ship propellers should withstand environmental conditions and remain stiff for long before replacement.

Edge-Resistance Blades

Once designed and molded into a perfect shape and edge, the blades retain that shape for long without any bends or dents. There is no need for grinding to reshape it as it can remain sharp for a while, enabling you to accomplish more jobs without considering a replacement or repair. This explains why lawn mover or farm tractors with titanium blades hardly need blade replacements.

Corrosion-Resistance

If you live in humid regions or use machines in humid environments like grass and forest, the best blade should be one that can withstand rusting. Once you have a titanium blade, you do not have to worry about rust removal, oiling, or painting to prevent rusting.

Even when left exposed to rust conditions longer, the blades remain attractive with no rust patches. This helps extend its longevity; however, you need frequent maintenance like cleaning to remove any mud and debris clogging between the blades.

Smother Cutting

A good cutting blade should ensure the edges are uniformly trimmed and smooth so anyone can comfortably walk on the grass. For twigs and branches, it should leave a clean cut without any rough edges. Due to the reduced friction effects, it can cut fast and uniformly. Regardless of the impact, it hardly succumbs to the impact of heat, which can lead to deformity and serrated edges.

Lighter Blades

A swordsman would prefer a titanium sword over others because of its lightness. A lighter sword is generally vulnerable to cracking, becoming blunt, or breaking upon contact with another. This is not the case with titanium blades. Despite being light, they are hard and can withstand higher impacts. You can easily swing it without much energy and only need to exert a limited force for maximum impact. When used in machines, they do not add any extra weight.

Whenever buying a sword, the greatest consideration should be the weight, stiffness, and ability to withstand environmental conditions like rust. Titanium sword blades are lighter yet harder to withstand various conditions; they hardly bend and maintain a stiff position, enabling the blade to remain straight.

Conclusion

The perfect blade should have titanium as the main component or an alloy. Due to its versatility, you can perfectly use it for heavy-duty cutting blades like saw, lawn mowing, and farm tractor blades. Since it is rust and corrosion-resistant, you can use it for blades exposed to wild environmental conditions like sea and atmospheric pressure. It serves all these roles adequately due to its stiff, rust, impact, and heat resistance capabilities.

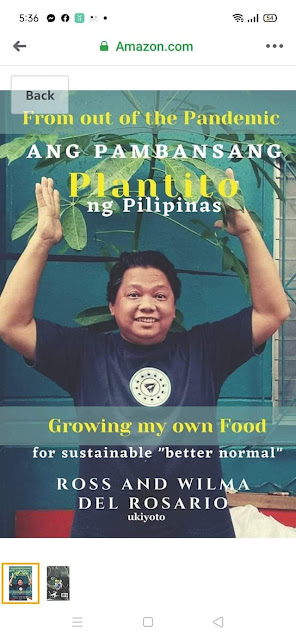

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

.jpg)

In general, mechanical processing of parts is the production of parts of various complexity, sharpening work, finishing operations - polishing, grinding, etc. The required level of deformation when processing a material is ensured by means of a cutting tool; the quality of processing, its productivity and cost depend on its geometry and design. Here you can find more information about the features of Alloy Steel machining services

ReplyDeleteThe inception of real-time streaming video software can be traced back to the early days of the internet when bandwidth limitations and technological constraints hindered its widespread adoption. However, with advancements in low latenecy streaming software internet infrastructure, compression algorithms, and video encoding standards, real-time streaming has become not only feasible but also highly efficient and reliable.

ReplyDelete