Wazzup Pilipinas !

The trend nowadays in modern economical living is "going up"....which means buying a condo.

I think condos are the most convenient investment nowadays where you really do not have to worry about any real estate complications because it will be the developer who would transact...

Saturday, March 9, 2013

Epson Showcases Environmentally-Sound Manufacturing Processes At Newly-Expanded Manufacturing Plant

Normal 0 false false false EN-US X-NONE X-NONE I have always been fascinated of seeing how things were made so it was a real treat to be able to join a plant tour where we were shown how printers and projectors...

Friday, March 8, 2013

Palaspas : Palm Leaf Weaving Techniques Workshop

Wazzup Pilipinas !

Craft MNL’s first heritage workshop brings you a session on learning native palm leaf weaving techniques.

Relive your childhoods with this session, as we play with woven stars,

balls, and fish. Learn weaving techniques that you can apply to

accessories, decor and functional...

Thursday, March 7, 2013

Grounded at the Lopez Museum : What's Keeping You From Flight?

Wazzup Pilipinas ! I am "Grounded".

Are we too tied up and "grounded" that it holds us back from our fullest potential?

We

try our best to exceed, excel and escape from the norm....but more

often than not, we end up getting criticized, questioned, and stricken

from the ranks of a so-called...

Wednesday, March 6, 2013

PH "More Fun" tops Thai International Travel Fair 2013

Honorable Jocelyn Batoon-Garcia, Philippine Ambassador to Thailand (fourth from left) visited the Philippine Booth

Wazzup Pilipinas !

The Department of Tourism (DOT) won the Best Booth Display during the Thai International Travel Fair held on 14 – 17 February 2013 in Bangkok, Thailand, extending...

Wicked Kitchen: An Awesome Adventure in Taste

Wazzup Pilipinas ! Its totally "wicked" !

One should exclaim similar words after a taste of the great meals available at Wicked Kitchen - that small yet full of potential restaurant just opposite the ABS-CBN building in Mother Ignacia.

I've learned that it has other branches in...

Tuesday, March 5, 2013

Lima Park Hotel : The Best Luxury Hotel in Lipa, Batangas

Wazzup Pilipinas !

Just in case you plan to witness some breathtaking views of the famed

Mt. Makiling and Mt. Malarayat, you can rest afterwards at the Lima Park Hotel located in the tranquil country setting of Lipa, Batangas. It is basically at the boundary of Lipa City and Malvar (the reason...

DOT and Puerto Princesa City Launch New Online Booking System for Underground River

Wazzup Pilipinas !

The Department of Tourism (DOT) and the

City Government of Puerto Princesa, Palawan have teamed up for the

launch of a new online booking system for local and foreign tourists

visiting the Puerto Princesa Underground River (PPUR).

Last February 7, 2013, the DOT...

Monday, March 4, 2013

Globe Refutes PLDT, Stands By Interconnection Issues

Normal 0 false false false EN-US X-NONE X-NONE ...

Sunday, March 3, 2013

Sugarleaf : Up Up And Away With Superfood!

Wazzup Pilipinas !

A superfood is a food rich in phytochemicals, which are special

compounts that have been noted to have disease-fighting properties.

These can reduce the risk of certain forms of cancer, reduce

inflammation, strengthen the immune systen, or in some other way...

Caffe Bene: The Coffee That's Just Right For Me

Wazzup Pilipinas !

Coffee was meant to be enjoyed as it is and not by the use of so much sweeteners and many other tidbits of add-ins. I was actually worried back then when coffee shops or cafes became a destination for whipped creamed and chocolate syrup-ed coffees. The real goodness...

Angono, Rizal : Nemiranda Art House - A Family's Art Showcase

Wazzup Pilipinas !

Angono, Rizal takes pride of having several museum destinations where one can also dine and marvel at the artistry in the form of sculptures, paintings and the likes. It seems its a place where the people were more into art and creativity. From the write-ups that I recently...

Wheatberry: Your Friendly Neighborhood Bakery and Cafe

Wazzup Pilipinas !

Wikipedia says the term wheatberry or wheat berry refers to the entire wheat kernel (except for the hull), composed of the bran, germ, and endosperm.

Wheatberries have a tan to reddish brown color and are available as

either a hard or soft processed grain. They are often...

Tang Brings Out The Hero in Every Kid

Wazzup Pilipinas !

Tang has been one of the very popular and recognizable powder juice drink since my childhood. It has more than one occasion been the families favorite juice drink. Since we are not so fond of softdrinks, the better alternative was juice, and the more economical was powdered...

Antistax : The Secret To Healthy Legs

Wazzup Pilipinas !

Got an invite for an event form a friend, and heard news that the product launch will empower women to be more confident and thus looking good both in and out. I never realized I will be in the midst of an audience where majority would be women.

Filipinas now have...

HTC Launches the Butterfly : The Ultimate Smartphone

Normal 0 false false false EN-US X-NONE X-NONE ...

Subscribe to:

Posts (Atom)

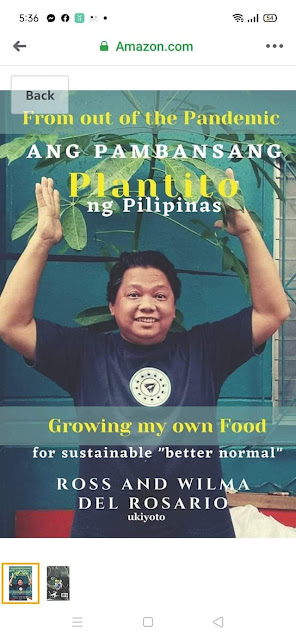

Ang Pambansang Blog ng Pilipinas Wazzup Pilipinas and the Umalohokans.

Ang Pambansang Blog ng Pilipinas celebrating 10th year of online presence

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

.jpg)