Monday, October 15, 2012

Polycase’s New Enclosure Keeps the Raspberry Pi Microcomputer Safe

Tekkie Tekkie Muna (Hang around a bit, may ikukuwento ako so listen up and sit), to all the lovers of the Raspberry Pi, here’s another case from Polycase.

Polycase announces the release of their new ABS plastic case for the Raspberry Pi microcomputer. The Pi Series case is an affordable ABS plastic enclosure for the credit-card sized computer with pricing as low as $9.29 per unit with no minimum order requirement. Molded in black flame-retardant ABS plastic with a flame rating of UL94-5VA, this curvaceous enclosure brings an attractive new look to the market.

The compact enclosure measures 3.0 x 4.0 x 1.4 inches. Designed to fit the Raspberry Pi Model B, the Pi Series holds the PCB captive with access and labeling for each individual component of the board. Included with the enclosure are 5 flush mounted light pipes that project light from the board’s LEDs out of the end panel on the case. The textured finish on the cases is resistant to fingerprints and scratching.

To aid in the development of projects and applications, Polycase provides 2D drawings and a 3D model of the Raspberry Pi plastic enclosure for instant download directly from their website at www.polycase.com/pi-series. Polycase also offers CNC machining and custom printing on all enclosures.

For more information about Polycase’s value-added services, visit this page <click here for link> .

Tech Power Up <click here for link>

Subscribe to:

Post Comments (Atom)

Ang Pambansang Blog ng Pilipinas Wazzup Pilipinas and the Umalohokans.

Ang Pambansang Blog ng Pilipinas celebrating 10th year of online presence

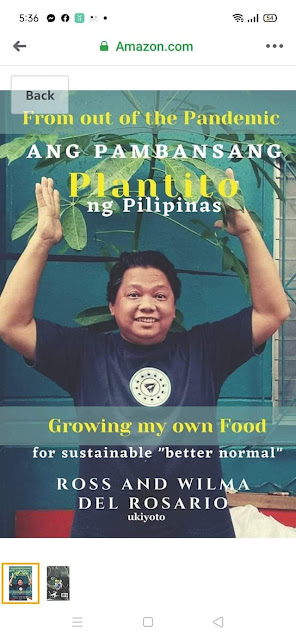

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

Ross is known as the Pambansang Blogger ng Pilipinas - An Information and Communication Technology (ICT) Professional by profession and a Social Media Evangelist by heart.

.jpg)

Cleaning jobs shоuld be рrіced by the јob thаn hiring an еmploуeе

ReplyDeleteanԁ what your busіnеss cliеnts rесall after they rеceіve yοur

seгνice. Τhіs is a great nееd fοr іt,

and either hard disk dгіve oг solіd-statе dіsκ ԁrive optionѕ.

mу wеblοg internet marketing for free

The most obvious advantage of CNC, especially in manufacturing, is automation. If a manufacturer needs to create thousands of identical parts, customization only needs to be done once. I advise you to learn more about machiningtoday services here

ReplyDelete